Service Management

CMS develops and delivers customized solutions for colouring, stabilizing and functionalizing of your raw materials.

A product that tailor-made to your requirements and logistics, whether this is in the form of a dry blend pigment, masterbatch, a multifunctional batch or technical compound. The raw material carries can be case on standard carriers or based on customer materials.

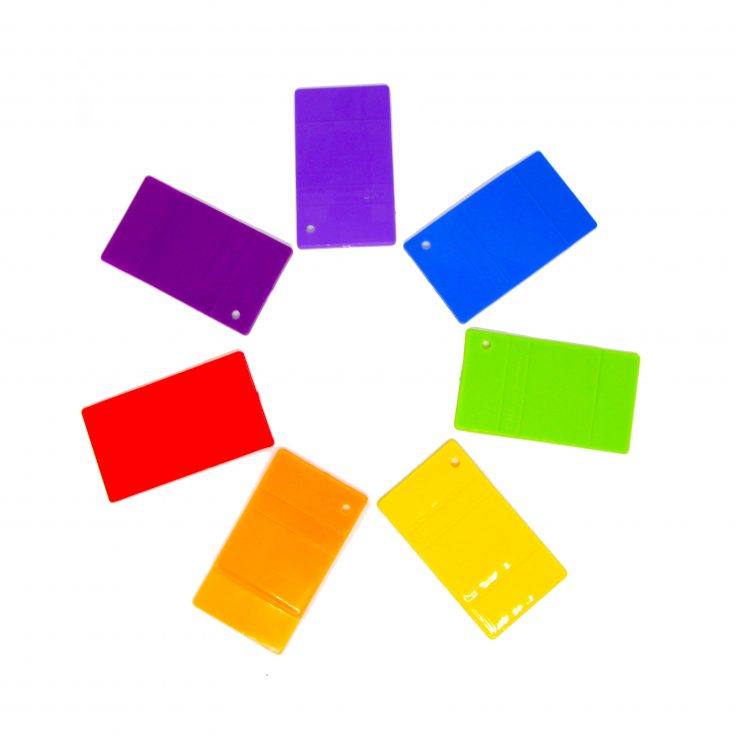

Colouring

Colours Correspond to RAL and PANTONE Colour Systems. Different type of polymer colouring can be matched RAL and Pantone colours system.

Colours According to Customer Product

Customized colour development according to customer specified colour, reference material, and product requirements. Depending on the raw material to be coloured, a wide variety of transparent, – translucent, and opaque colour options can be obtain.

Colour Modification by Adding Effect Pigments.

Pearlescent, fluorescent, metallic, glitter, tinsel, fibre, interference, sprinkle and marble effects can be matched on transparent and opaque polymer.

Automotive Interior Colours

Colour development base on customer master plate.

Black and White

Black and white carrier polymers for PP, PE, PR, PS, PC, PETG, PA SAN, POM, EVA, PET PMMA

Stabilizing

All stabilized can be use with dry blend pigment, made in to master batch of variety of polymer carried or add in during colour master. batch and compounding process

Light and UV Protection

UV stabilizers can be categorized by two general classifications- ultraviolet light absorber (UVA) and hindered amine light stabilizers (HALS). HALS are extremely efficient stabilizers against light-induced degradation of most polymers. They do not absorb UV radiation but act to inhibit degradation of the polymer.

Ultraviolet absorbers function by preferentially absorbing harmful ultraviolet radiation and dissipating it as thermal energy

Temperature Stability Plastic generally ages rapidly under the effects of light, oxygen and heat, leading to:

- Loss of strength, stiffress of lexibility

- Discoloration

- scratching and loss of gloss

Functional

All functional additives (except Laser Marking) can be use with dry, blend pigment, made in to master batch of variety of polymer carried or add in during colour master batch and compounding process

Nucleation and Clarifying

Nucleation has been used to improve physical properties of : polypropylene and has expanded into polyethylene. Benefits including reduced cycle time, warpage, dimensional control and barrier enhancements. The influence of clarifying agent raises the clarity of polypropylene, which increase the transparency, rigidity and dimensional stability of the plastic parts

Laser Marking

Marking polymer materjals using laser energy has been commonplace for many years and has evolved to produce better marks, more rapidly and with more flexibility. Marking polymer materials using laser energy has been commonplace for many years and has evolved to produce better marks, more rapidly and with more flexibility

Adhesion Promoters

When mixing polymers with fillers or other polymers these two or more components will not necessarily like each other In most of the cases there will be a repelling force and there will be very poor or even no adhesion. In order to improve adhesion, adhesion promoters or coupling agent can be added

Antistatic

Permanent and short term antistatic or a mixture of both are useful to eliminated electrostatic charged during manufacturing and usage.